About Hopzoil™

Beer brewers have discovered that using Hopzoil can reduce dry-hopping costs and frustration, along with reducing labor, freight, and storage costs, as well as increasing yield and aroma. This results in more profits per batch brewed.

Brewers tell us…

“this is the future”.

Think of it as Liquid Dry-Hopping.

Brewers who have either partially or fully substituted their dry-hopping with pellets for Hopzoil™ have reported increased yield and profit with each batch. Brewers report average yield gains of 5% to 30% or more.

That’s a lot of free beer.

American hop-forward beer flavors typically “drop off a cliff” at 60-90 days. Tests are showing that using Hopzoil extends hop flavor shelf life in beer by a factor of three to five times. Hop aroma and flavor drop-off is mitigated by adding as little as 2 ml/BBL to bright beer.

Keep your serving tanks fresh longer.

In addition, reduced freight and storage costs increased shelf-life, and ease-of-use advantages all impact your bottom line, along with an increase in throughput, from reduced dry-hopping time.

Increased shelf-life

Eliminate out-of-date beer buybacks from Distributors.

The shelf life of Hopzoil in the bulk container is five years…typically a longer shelf life than pellets.

Eliminate out-of-date beer buybacks from Distributors.

The shelf life of Hopzoil in the bulk container is five years…typically a longer shelf life than pellets.

Eliminate Hop Creep & Hop Burn

Retain all the bitterness that is normally stripped during dry-hopping incremental fermentation. Solving DO2, re-attenuation, and diacetyl issues are all key advantages of Hopzoil. The MBAA Technical Report (Q3 2016) concludes that pure hop oil does not affect IBU test results.

Add Intense “Fresh-Hop” Aroma

Hopzoil™ provides an intense freshness that cannot be replicated with dried processed hops. The result captures the complex “fresh hop” aroma and flavor… that you can use year-round.

Hopzoil™ Checks all the Boxes

Hopzoil™ Checks all the Boxes

Intense, Aromatic Hop Aroma and Flavor

- Continued flavor “bloom” 24-48 hours after dosing, even in package

Easy One-Step Addition

- Ready-to-use out of the container. No prepping is needed. No ethanol.

- Predictable and consistent dosing

- Micro-accuracy for reducing dosing variances

Eliminate “Hop Creep”

- Reduce bittering/IBU stripping

- Eliminate unpredictable, dry-hop-induced diacetyl formation

- Eliminate “hop burn”

- Eliminate over-pressurization due to increased CO2—a safety risk

- Eliminate the need for extended cellaring, thereby freeing up tank space

- Eliminate green biomass, which leads to Hop Creep in the first place

Significantly Extend Shelf-life in Hop-Forward Beers

- 3-6 times longer shelf-life in hop-forward beers, like IPAs

- Eliminate costly buy-backs of expired beer from distributors

- Stays emulsified for up to 12 months in packaged beer

R&D Advantages

- Ease of blending different oil varieties for your own proprietary sensory profiles

- Reduce “test batch” turnaround time from days to hours

TTB Approved Ingredient for all Malt Beverages

Processing Gains: More Revenue per Batch, for a Better Bottom Line

- Reduce filtration losses, increase yield per batch

- Completely eliminates on-site ethanol emulsification step from the PURE version

- Reduced kettle time vs. dry-hopping with pellets

- Instant tank-dosing to carbonation to packaging. Pack out immediately after carb.

- Quick and easy cleanup. Wipes clean with water.

- Increase throughput; faster turnover of batches, efficient asset use

- Brewing efficiency: Create multiple beers from one foundation base

- Reduce hop pellet bill per batch

- Bulk Hopzoil shelf life in the container is at least 5 years!

Reduce Shipping and Freezer Storage Costs

- A fraction of the shipping cost vs. a pallet of processed hops

- Reduce freezer storage space requirements

- Can be stored at room temperature until opened

A Differentiation for Craft Brewers

Reduce Carbon Footprint; Adds Sustainability

- No fossil fuels for drying hops and fewer fossil fuels for transport

- Lower energy costs for storage

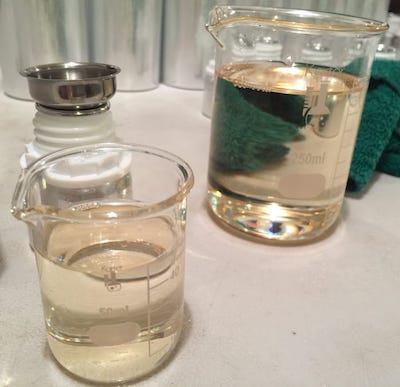

Uniquely Different Among Hop Extracts

We start with a different raw ingredient… Fresh hops, which are available only at harvest time, are right out of the field. Hopzoil™ does not use dried, processed hops. Fresh hops contain all the volatile, most aromatic oils, captured at the peak of freshness, and you can’t get any fresher than this.

All brewers know that heat volatilizes and evaporates these most aromatic of hop oils. You can’t put back into a raw ingredient what has been taken out during drying or processing. It’s made using our Proprietary Process.

We use a Different Extraction Process

Hopzoil™ takes fresh hops, and steam-distills them, right on the farm. We use pure steam, rather than a CO2 or other solvent-based extract process. This process allows us to capture the “freshness” of fresh hops, retaining the intensely complex floral, citrus, tropical fruit, and piney aromas, similar to what you would expect in any given variety, but more intense.

The Result is Very Different

Hopzoil™ provides an intense freshness and sensory impact that cannot be replicated with dried processed hops.

- More Revenue with Every Batch

- Reduce Costs

- Shipping, storage space, no freezer storage

- Easy Dosing

- Increase your Sustainable Profile

Your Bottom Line

Higher Yield Per Batch: Reduce or eliminate dry-hopping pellets, and your filtration losses (and labor) will plummet, increasing your yield and profit.

More Profit Per Batch: A higher yield means more beer to sell, making you more money per batch.

Retain all the Bitterness: Dry hopping with pellets can strip the bitterness you worked so hard to achieve during the brewing process. Hopzoil does not affect the IBU test results.

Reduce Dry-Hopping Pellets, Reduce Your Hop Bill Per Batch. Think of the process as “liquid dry-hopping”

Reduce Shipping Costs: One liter is enough for approximately 200 barrels, as opposed to shipping 5 boxes of frozen pellets.

Reduce Storage Space: Hopzoil is stored at room temperature saving you precious freezer storage space.

Long Shelf-Life: Hopzoil retains full potency for years. Added to beer can help to keep “fresh” taste and aroma over time, longer than pellets.

Reduce Carbon Footprint: No energy used to dry, bale, and pelletize hops; less volume to ship and store; minimal waste.